Written by Douglas Mothersell, Senior Member of Twisted Willow Fabrication, LLC.

My background is in heavy equipment. I have a degree in heavy equipment repair as well as hydraulic and pneumatic systems. My experience has not only been in equipment repair, but also in the setup of specialized equipment, build specifications, and specialized tool development and fabrication. This experience includes the industrial/municipal setting. Our new product line stems from the specialized needs of these industries and my involvement with them.

Several years ago I started looking at mid-sized industrial vacuum systems for use at a large municipality. The equipment I’m referring to is truck or trailer mounted and is intended to clean large areas or perform low impact excavation. It often has a gasoline or diesel engine driving a blower unit moving air in the neighborhood of 500 to 1000 or more cubic feet per minute. These units are usually vacuum rated around 15 inches of mercury and use 3 to 4 inch diameter suction hose. They often have some kind of tank or tanks to collect liquid and debris.

These machines and the crews that use them are the workhorses of the commercial cleaning and excavating industries. It is not easy work and the crews that do this work take it seriously. The crews I talked to were very generous with their time, showing me their equipment, explaining how it worked and how they did their job. At that time the company that sent me to check this equipment decided not to invest in it, but I continued to explore the possibilities in this industry. I continued to talk to crews and salesmen. Researched on the internet and talked to a consultant. You see, since my career started, inefficiency has always bothered me. I’ve been trained to notice it and I try to fix it. What I’ve noticed with this vacuum equipment is the lack of tooling that should support it. They can be used better. They can be more efficient.

Creating an Industrial Vacuum Product Line for More Efficiency

I stayed focused on what I was originally sent to look at, the use of mid-sized vacuum equipment in the industrial cleaning setting. Crews doing this work clean up after floods or hurricanes devastate an area. They clean shopping centers, stadiums and parking garages. They clean up after oil and fracking fluid spills. Water and sewer municipalities use them for tank and basin cleaning and after installing pipelines. Usually crews are using one or two suction hoses with one end connected to the vacuum unit and the other end connected to some kind of suction tool. Crews also employ pressure washers and fire hoses to get their wash water. Other tools like squeegees and brooms are also used. Whatever has been collected by one of these vacuum units must then be removed and disposed of properly. The problem that is easy to see is that very few specialized tools are available for use with these vacuum units. Small suction cleaning wands are plentiful and large suction pickup tubes can be purchased, but one or two hand tools on a machine that produces 800 to 1000 cubic feet per minute (CFM) of air movement and 15 inches of mercury (inHg) suction is not efficient. The vacuum unit can do a lot of work very quickly with the proper tools. That’s where our product line comes in.

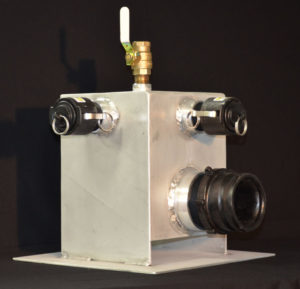

I like things that work together. You’ll often hear me use the word “system”. The tools in our new product line can be used individually or together as a system to make your vacuum machine and crew more productive. In the next few weeks Twisted Willow Fabrication will be introducing this equipment one at a time; Twisted Willow’s Collector Pod, Suction Pod, 4×4 Splitter and 2×4 Splitter.

These tools have been in design for a few years, prototyped and tested last year. This equipment has been designed by and is manufactured by Twisted Willow Fabrication. Built entirely out of lightweight aluminum, this precision CNC cut equipment is easy to handle and store and will not rust. By design this equipment will not capture or hold material, so it’s self-cleaning when you clean up at the end of a job. As always, Twisted Willow Fabrication will customize the common platform of our equipment to suit your needs. We describe ourselves as a custom metal fabrication shop. We take pride in that. Feel free to contact us. You’ll get the fastest answer by emailing us at twistedwillowfabrication@gmail.com.