It’s been a busy two years. A year and a half ago Twisted Willow Fabrication LLC was formed. We had a lot of time setting up the business before that. In the past year and a half we moved from one shop to another, setting up our new business and work area. We went from a small general fabrication shop to the next step, a small to mid-sized custom metal fabrication shop. Getting into the mid-sized arena meant we had to have ways of handling and processing raw metals. The processing part came with the additional tools we invested in. But the handling part was on us. You have seen in past blog posts and Facebook posts that we have built two gantry cranes to handle the increased steel weight we now have to deal with. You have also seen the specialized welding table we designed and fabricated. There are also heavy duty stands and carts for metal and equipment. Those fabricated tools came in the order we needed them. There has been one last thing hounding us: material storage.

Designing a Metal Storage Rack for Shop Inventory

We have had some of our raw material in the new shop, some in the old shop and some in a barn. It’s tough knowing what you have. We can inventory material, but if we can’t find it we waste time looking. The long term plan has always included a metal storage rack. Because we have to pay the bills and put out work, our stuff has had to wait. Our metal storage rack will wait no longer.

The CAD and CNC Process

The project was designed on CAD and implemented. What we ended up with was exactly what we wanted, and because it was designed on CAD and turned over to CAM/CNC plasma cutting, it went together perfectly. Even though we do it all the time, it’s still gratifying to see a project go from blueprints to perfectly fitting parts or assemblies. In the old days we took blueprints to the product and then performed manual setups and then we manually processed the part. Technology has made it so blueprints and cut files happen on the screen of the computer. Layout lines, bolt hole centers, radius corners are all done now on the computer without laying a hand on measuring equipment or raw material. Parts are perfect and repeatable. The job now goes from planning to blueprints to cut files without having to be in the shop. Nowadays, if a shop is not using CNC equipment, it’s not competing. But I digress. Back to our metal rack.

So……we built a metal storage rack. A heavy duty industrial metal storage rack. It is designed for our gantries to straddle and pull off material to be processed. We can now view and easily retrieve inventoried material. We can also stock material for commercial customers. We look more professional and the shop is easier to clean.

Putting the Pieces Together

The long and the short of it is that we had Hal, our CNC plasma table, cut out 48 arms (actually arm halves) and centers. He also cut out spreader bar plates and upright top plates. The arm halves and centers were assembled to create a perfectly fitting arm assembly that was placed over a tubular upright leg and then welded. Opposing 2×6 channel was used for the upright feet. The feet and top plates hold the upright assembly together, the welded arm assemblies hold our raw material in tiers off the floor. Spreader bar assemblies keep the uprights properly spaced and standing. An Axalta Imron Polyurethane DTM paint job finishes the project. A year and a half after Twisted Willow Fabrication was formed, we now have our metal rack. But don’t just take our word for it, see all stages of the fabrication process in the gallery below.

Gallery

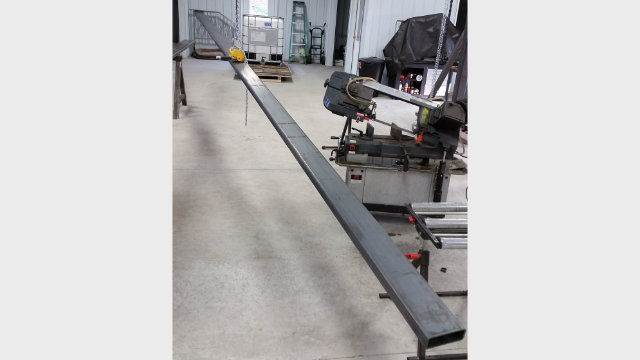

- Moving frame piece with our magnet for cutting

- Cutting frame

- Arm pieces fresh off of HAL (our plasma table)

- Arm pieces lined up ready to be welded

- Welding an arm

- Welding an arm

- Welded arm ready to place on frame

- Completed rack section moved to paint room

- Finished, but empty, metal storage rack in place

- What a difference an inventory makes!